Integrated Mine Plan Complete with Estimated Net Present Value of $1.6 billion

Average Annual Production of 4.7 Million Tons at First Quartile Cost and Mine Life of 25+ years

ST. LOUIS, Oct. 11, 2024 /PRNewswire/ — Peabody (NYSE: BTU) today provided an investor presentation on project development and the related integrated mine plan at Centurion, the Company’s premium low volatile hard coking coal project located in Australia’s Bowen Basin. The Company will hold a conference call on Monday, October 14, 2024, at 3:00 p.m. CST to share a comprehensive update on Peabody’s development of Centurion. To watch the event live or access a replay, please visit www.peabodyenergy.com.

Centurion is quickly becoming the cornerstone metallurgical coal asset in Peabody’s global coal portfolio, unlocking substantial, untapped reserves and repositioning Peabody as primarily a metallurgical coal producer. “The development of Centurion is a key strategic priority to maximize shareholder value and reweight our portfolio and long-term cashflows to metallurgical coal,” Jim Grech, Peabody’s President and Chief Executive Officer, said. “Combined with Peabody’s diversified portfolio, resilient balance sheet, fully funded reclamation obligations and robust shareholder return program, Peabody is uniquely positioned as a leading global coal producer.”

Thus far, two continuous miner units have been commissioned and the mine successfully produced its first development coal in June. The prep plant successfully washed its first coal and moved it to stockpile via the overhead belts in September. Peabody expects to commission a third continuous miner and ship the first cargo of coal in the fourth quarter.

Centurion is set to significantly enhance Peabody’s metallurgical coal production with average volume of 4.7 million tons per year at expected costs of $105 per ton over the twenty-five plus year life of the mine. Centurion will also reposition the metallurgical coal portfolio toward higher quality premium met coals.

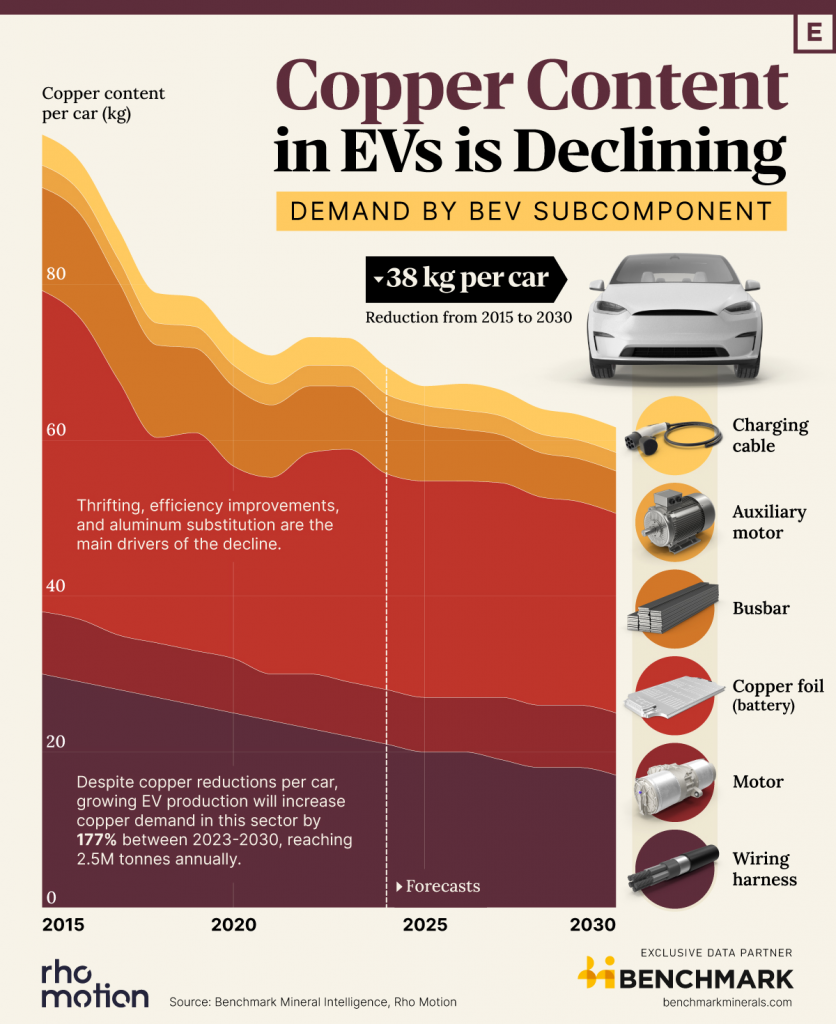

“We anticipate demand for premium hard coking coals to grow significantly,” Malcolm Roberts, Peabody’s Chief Marketing Officer, said. “While demand for this product continues to grow, new projects are increasingly rare, making Centurion’s product highly sought after.”

At September 30, 2024, Peabody has completed approximately $250 million of the anticipated $489 million of initial development capital to achieve longwall production in March 2026. With a $210 per metric ton benchmark price assumption, Centurion has an estimated net present value of $1.6 billion and a 25 percent internal rate of return.

“Peabody is committed to increasing shareholder value through a balanced approach of maximizing shareholder returns and developing Centurion,” Mark Spurbeck, Peabody’s Chief Financial Officer, said. “Centurion provides increased optionality to tightening metallurgical coal markets and will be a strategic asset in Peabody’s global coal portfolio for decades.”

Concurrent with this release, Peabody has issued a presentation on the Centurion project that can be found on the investor section of www.peabodyenergy.com.

Peabody (NYSE: BTU) is a leading coal producer, providing essential products for the production of affordable, reliable energy and steel. Our commitment to sustainability underpins everything we do and shapes our strategy for the future. For further information, visit www.PeabodyEnergy.com.

Contact:

Karla Kimrey

ir@peabodyenergy.com

Forward-Looking Statements

This press release contains forward-looking statements within the meaning of the securities laws. Forward-looking statements can be identified by the fact that they do not relate strictly to historical or current facts. They often include words or variation of words such as “expects,” “anticipates,” “intends,” “plans,” “believes,” “seeks,” “estimates,” “projects,” “forecasts,” “targets,” “would,” “will,” “should,” “goal,” “could” or “may” or other similar expressions. Forward-looking statements provide management’s or the Board’s current expectations or predictions of future conditions, events or results. All statements that address operating performance, events, or developments that may occur in the future are forward-looking statements, including statements regarding the shareholder return framework, execution of Peabody’s operating plans, market conditions, reclamation obligations, financial outlook, potential acquisitions and strategic investments, and liquidity requirements. They may include estimates of sales and other operating performance targets, cost savings, capital expenditures, other expense items, actions relating to strategic initiatives, demand for the company’s products, liquidity, capital structure, market share, industry volume, other financial items, descriptions of management’s plans or objectives for future operations and descriptions of assumptions underlying any of the above. All forward-looking statements speak only as of the date they are made and reflect Peabody’s good faith beliefs, assumptions and expectations, but they are not guarantees of future performance or events. Furthermore, Peabody disclaims any obligation to publicly update or revise any forward-looking statement, except as required by law. By their nature, forward-looking statements are subject to risks and uncertainties that could cause actual results to differ materially from those suggested by the forward-looking statements. Factors that might cause such differences include, but are not limited to, a variety of economic, competitive, and regulatory factors, many of which are beyond Peabody’s control, that are described in Peabody’s periodic reports filed with the SEC including its Annual Report on Form 10-K for the fiscal year ended Dec. 31, 2023 and Quarterly Report on Form 10-Q for the quarter ended Jun. 30, 2024 and other factors that Peabody may describe from time to time in other filings with the SEC. You may get such filings for free at Peabody’s website at www.peabodyenergy.com. You should understand that it is not possible to predict or identify all such factors and, consequently, you should not consider any such list to be a complete set of all potential risks or uncertainties.

View original content to download multimedia:https://www.prnewswire.com/news-releases/peabody-provides-update-on-centurion-metallurgical-coal-mine-development-302274253.html

SOURCE Peabody