Vancouver, British Columbia–(Newsfile Corp. – February 6, 2024) – Goldshore Resources Inc. (TSXV: GSHR) (OTCQB: GSHRF) (FSE: 8X00) (“Goldshore” or the “Company“) is pleased to announce an updated mineral resource estimate (the “MRE“) for the Moss deposit (“Moss” or the “Moss Deposit“) and East Coldstream deposit (“East Coldstream” or the “East Coldstream Deposit“), both located at its 100%-owned Moss Gold Project in Northwest Ontario, Canada (the “Moss Gold Project” or the “Project“).

Highlights of the 2024 Mineral Resource Estimate Update:

- Upgrading of the MRE to include 23% Indicated Mineral Resources and an increase in the average grade over the 2023 MRE.

- Indicated Mineral Resource of 1,535 thousand ounces grading 1.23 grams per tonne gold (g/t Au), contained within 38.96 million tonnes.

- Inferred Mineral Resource of 5,198 thousand ounces grading 1.11 grams per tonne gold (g/t Au), contained within 146.24 million tonnes.

- The total resource tonnage increase is just under 1% overall over the 2023 MRE, however the overall grade increase versus the 2023 MRE is approximately 11%.

- The shears that host gold mineralization have been extensively remodelled as constraining domains, greatly enhancing the reliability of the current MRE.

- With gold prices consistent with the 2023 MRE, 94% of the 2024 MRE’s tonnes and gold ounces are contained within these shear models.

- This is a significant increase compared to the 2023 MRE, where only 35% of the tonnes and 65% of the gold ounces were contained in its shear model.

- Implied stripping ratios based on diluted block models and the Reasonable Potential for Eventual Economic Extraction (“RPEEE“) constraining pit optimization are 3:1 for Moss and 6:1 for East Coldstream.

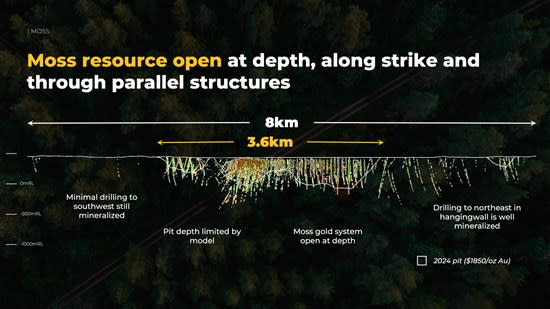

- The pit depth is constrained by the model (in multiple locations), indicating the potential for a larger pit should the model be extended at depth.

- The 2024 Moss Project MRE update is set to be the foundation for resource growth and development towards Tier One status, and leading to a future Preliminary Economic Assessment (PEA).

- All identified zones within the Project are still open to potential expansion.

- The Moss Project encompasses 36 satellite targets, including several mapped and sampled gold trends near the Moss Gold Deposit, offering prospects for discoveries and additional gold mineralization.

Table 1: Moss Project Updated Mineral Resource Estimate

| Indicated | Inferred | |||||||

| Cutoff | Tonnes | Grade | Metal | Tonnes | Grade | Metal | ||

| (g/t Au) | (Mt) | (g/t Au) | (Koz Au) | (Mt) | (g/t Au) | (Koz Au) | ||

| Moss | ||||||||

| Open Pit | Core Shears | 0.35 | 19.95 | 1.39 | 893 | 56.32 | 1.39 | 2,525 |

| Marginal Shears | 0.35 | 11.35 | 0.92 | 335 | 70.31 | 0.81 | 1,836 | |

| Low Grade Halo | 0.35 | – | – | – | 10.21 | 0.62 | 202 | |

| Open Pit Subtotal | 31.30 | 1.22 | 1,228 | 136.84 | 1.04 | 4,563 | ||

| Underground | 2.0 | – | – | – | 3.22 | 3.43 | 355 | |

| Moss Total | 0.35/2.0 | 31.30 | 1.22 | 1,228 | 140.07 | 1.09 | 4,919 | |

| East Coldstream | ||||||||

| Open Pit | 0.35 | 7.67 | 1.25 | 307 | 5.36 | 1.15 | 198 | |

| Underground | 2.0 | – | – | – | 0.82 | 3.10 | 82 | |

| E Coldstream Total | 0.35/2.0 | 7.67 | 1.25 | 307 | 6.18 | 1.41 | 280 | |

| Grand Total | 0.35/2.0 | 38.96 | 1.23 | 1,535 | 146.24 | 1.11 | 5,198 | |

Notes:

- The 2024 Moss Mineral Resources were estimated and classified in accordance with the Canadian Institute of Mining, Metallurgy and Petroleum (“CIM”) “Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines” dated November 29, 2019, and the CIM “Definition Standards for Mineral Resources and Mineral Reserves” dated May 10, 2014.

- Mr. Michael Dufresne, M.Sc., P.Geol., P.Geo. and Mr. Warren Black, M.Sc., P.Geo. both of APEX Geoscience Ltd. (“APEX“) qualified persons as defined by NI 43-101, are responsible for completing the updated mineral resource estimation, effective January 31, 2024.

- Mineral resources that are not mineral reserves have no demonstrated economic viability. No mineral reserves have been calculated for Moss. There is no guarantee that any part of the mineral resources discussed herein will be converted to a mineral reserve in the future.

- The estimate of mineral resources may be materially affected by environmental, permitting, legal, title, market, or other relevant factors.

- The quantity and grade of reported Inferred Resources is uncertain, and there has not been sufficient work to define the Inferred Mineral Resource as an Indicated or Measured Mineral Resource. It is reasonably expected that most of the Inferred Mineral Resources could be upgraded to Indicated Mineral Resources with continued exploration.

- The historical underground voids from mining in any of the deposit areas have been removed.

- All figures are rounded to reflect the relative accuracy of the estimates. Totals may not sum due to rounding. Resources are presented as undiluted and in situ.

- Tonnage estimates are based on individually measured and calculated bulk densities for geological units ranging from 2.68 to 2.89 g/cm³. Overburden density is set at 1.8 g/cm³.

- Metal prices are US$1,850/oz Au with a revenue factor of 1 and recovery of 90% for Moss and 95% for East Coldstream.

- Open-pit resource economic assumptions are mining costs of US$2.25/waste tonne, $3.00/ore tonne, flotation-leaching processing costs of US$9.50 per tonne, and mine-site administration costs of US$2.10 per tonne processed.

- Open-pit resources comprise blocks constrained by the pit shell resulting from the pseudoflow optimization using the open-pit economic assumptions and 50° pit slopes.

- Underground resource economic assumptions are US$75/tonne for mining mineralized and waste material and US$9.50/tonne for processing. The underground resource mining assumptions are open pit stope mining method with a minimum mining width of 1.5m and a minimum stope volume equal to stope dimensions of 1.5m x 10m x 20m.

- The Underground material below the open pit was manually constrained to continuous material above the gold cutoff (2.0 g/t) that met the minimum thickness and volume requirements. Resources not meeting these size criteria are included if they maintain a grade above the cutoff once diluted to the required size.

Table 2: Moss Project Updated Open Pit Mineral Resource Estimate Sensitivity

| Cutoff (g/t Au) | Indicated | Inferred | ||||

| Tonnes (Mt) | Grade (g/t Au) | Metal (Koz Au) | Tonnes (Mt) | Grade (g/t Au) | Metal (Koz Au) | |

| Moss | ||||||

| 0.2 | 33.55 | 1.16 | 1,249 | 185.72 | 0.83 | 4,985 |

| 0.3 | 32.36 | 1.19 | 1,239 | 150.61 | 0.97 | 4,707 |

| 0.35 | 31.30 | 1.22 | 1,228 | 136.84 | 1.04 | 4,563 |

| 0.4 | 30.15 | 1.25 | 1,214 | 125.85 | 1.10 | 4,431 |

| 0.5 | 27.31 | 1.34 | 1,173 | 104.78 | 1.22 | 4,126 |

| 0.6 | 24.05 | 1.44 | 1,115 | 86.6 | 1.37 | 3,807 |

| 0.8 | 17.88 | 1.70 | 977 | 60.33 | 1.66 | 3,221 |

| 1.0 | 13.00 | 2.00 | 836 | 42.89 | 1.97 | 2,721 |

| East Coldstream | ||||||

| 0.2 | 8.70 | 1.13 | 316 | 6.54 | 0.99 | 208 |

| 0.3 | 8.01 | 1.21 | 311 | 5.73 | 1.09 | 201 |

| 0.35 | 7.66 | 1.25 | 307 | 5.35 | 1.15 | 198 |

| 0.4 | 7.33 | 1.29 | 303 | 4.99 | 1.20 | 193 |

| 0.5 | 6.59 | 1.38 | 292 | 4.36 | 1.31 | 184 |

| 0.6 | 5.92 | 1.47 | 280 | 3.77 | 1.43 | 174 |

| 0.8 | 4.58 | 1.70 | 250 | 2.94 | 1.64 | 155 |

| 1.0 | 3.49 | 1.95 | 219 | 2.31 | 1.84 | 137 |

See footnotes for Table 1

Table 3: Moss Project Updated Underground Mineral Resource Estimate Sensitivity

| Cutoff (g/t Au) | Inferred | ||

| Tonnes (Mt) | Grade (g/t Au) | Metal (Koz Au) | |

| Moss | |||

| 1.8 | 3.96 | 3.14 | 400 |

| 1.9 | 3.56 | 3.29 | 377 |

| 2.0 | 3.22 | 3.43 | 355 |

| 2.1 | 2.89 | 3.59 | 334 |

| 2.2 | 2.60 | 3.75 | 314 |

| 2.4 | 2.11 | 4.09 | 277 |

| East Coldstream | |||

| 1.8 | 1.00 | 2.88 | 93 |

| 1.9 | 0.90 | 3.00 | 87 |

| 2.0 | 0.82 | 3.10 | 82 |

| 2.1 | 0.76 | 3.19 | 78 |

| 2.2 | 0.70 | 3.28 | 74 |

| 2.4 | 0.60 | 3.45 | 66 |

See footnotes for Table 1

President and CEO Brett Richards stated: “The MRE results above are extremely encouraging, and validate the strategic exploration and drilling campaign we embarked on almost 3 years ago. We have consistently delivered exciting drilling results as they relate to the Moss Gold Project, and this MRE illustrates a meaningful and material increase in the quality, quantity, and grade of the deposit. Conducting this update to the MRE was the logical next step in defining our strategy going forward of understanding and defining the potential of the Moss Gold Project; in an effort to maximize shareholder value. We continue to believe that the Moss Gold Project will be a sector anomaly of having top quartile grade and top quartile size and scale within our comparable peers; as it moves closer to being a Tier One asset.”

Figure 1: Location of Moss Deposit and East Coldstream Deposit in the Moss Gold Project

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8051/196910_5cf9a22b6498bbf1_002full.jpg

Figure 2: Plan of Moss showing shears, $1,850 pit shell and mapped mineralized trends

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8051/196910_5cf9a22b6498bbf1_003full.jpg

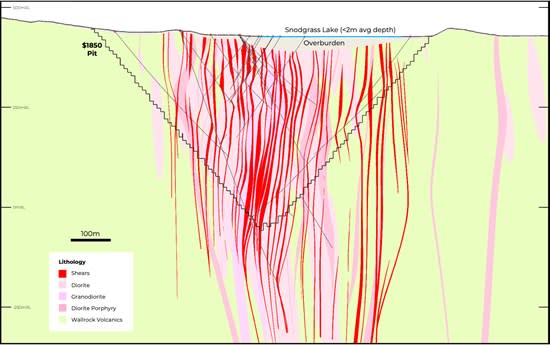

Figure 3: Cross section through the Moss Main Zone showing geology

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8051/196910_5cf9a22b6498bbf1_004full.jpg

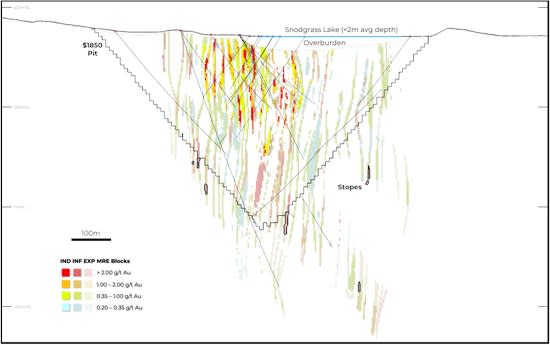

Figure 4: Cross section through the Moss Main Zone showing grade model, $1850 open pit shell and modelled stopes

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8051/196910_5cf9a22b6498bbf1_005full.jpg

Figure 5: Plan of East Coldstream showing shears, cross-cutting diabase dike and $1,850 pit shell

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8051/196910_5cf9a22b6498bbf1_006full.jpg

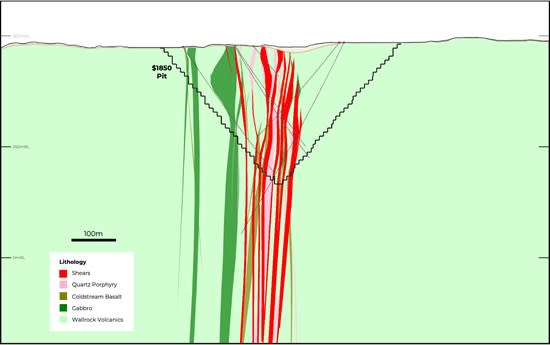

Figure 6: Cross section through East Coldstream showing geology

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8051/196910_5cf9a22b6498bbf1_007full.jpg

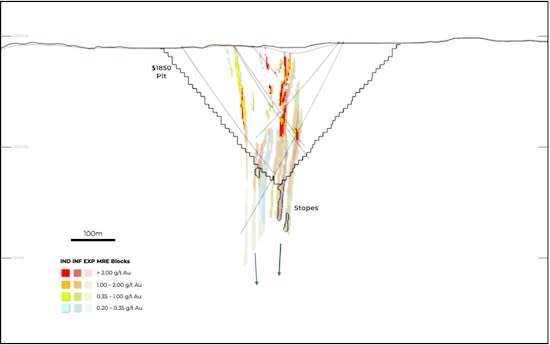

Figure 7: Cross section through East Coldstream showing grade model, $1,850 open pit shell and modelled stopes

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8051/196910_5cf9a22b6498bbf1_008full.jpg

Technical Overview

Historical Assay Review

APEX Geoscience Ltd. (“APEX“) completed an in-depth review and validation of assays collected before 2010 at the Moss Deposit and East Coldstream Deposit to establish whether the data is suitable for mineral resource estimation. APEX reviewed previous studies’ evaluation of twin drilling and resampling programs and drew the following conclusions regarding this data:

- Five twin holes have been completed in the Moss Zone. APEX regards this dataset as limited, insufficient for definitive conclusions, but adequate for a preliminary assessment. This view is due to the deposit’s characteristics and challenges in accurately positioning twin holes adjacent to historical holes. The data indicate that the twin holes generally exhibit mineralization that corresponds with the mineralization trends noted in the historical drillholes they were designed to test and confirm.

- Six historical drillholes were resampled to determine potential bias in the historical dataset.

- Prior analyses of the resampling program focused on comparing the difference between each interval’s historical and modern assays and noting variance discrepancies between the two datasets.

- APEX performed a quantile-to-quantile comparison between resampled and historical assays and the results show similar distributions, indicating no significant bias in resampling assay values vs original values.

- APEX considers the noted variance difference to be within expected ranges, as the differences in sampling volumes could explain any discrepancies.

- These findings remain partially inconclusive due to the limited number of holes resampled.

Due to the inconclusive results from the twinning and resampling programs, APEX conducted a spatial pairing analysis. This analysis compared the distribution of historical assays with modern drilling data. The assay data was limited to samples within the 2023 modelled shear domains, ensuring only assays from similar geological settings were compared. In this analysis, only assays from either dataset that are within 15 meters of an assay from the other dataset could be considered. The dataset included thousands of paired samples to complete the analysis on. Below are APEX’s conclusions:

- The assay distributions of historical paired data and modern paired data were found to be similar after accounting for comparable mineralization zones.

- No evident bias in historical assays was observed that could be attributed to assay methods or assay labs or different generations (ages) of data.

- Some historical data involved selective assaying. Inserting nominal waste values for unsampled intervals yields a conservative gold content estimate at the sample location.

Based upon this analysis, the QP believes that the historical assays can be used for a mineral resource estimate even with limited historical QA/QC data. Details of the Historical Assay Review and Analysis will be provided in a technical report with an effective date of January 31, 2024, prepared in accordance with National Instrument 43-101 (“NI 43-101“) standards.

Moss Deposit Geology

The Moss Deposit is a structurally controlled gold deposit within the greenstone terrain of the Shebandowan Belt in the Archean Superior Province. Mineralization is localized where the major NE-trending Wawiag Fault Zone cuts a dioritic to granodioritic intrusion complex. The deposit comprises a network of centimetre- to meter-scale northeast-trending shear zones hosting high-grade gold mineralization. Surrounding the shear zones are areas of lower-grade gold mineralization associated with less intense shearing and more brittle deformation. This includes veining in both the intrusion rock and adjacent wall rocks between the shear zones. Mineralization is associated with pyrite, sericite and chlorite alteration and millimetre- to centimetre-scale irregular quartz-carbonate veinlets.

East Coldstream Deposit Geology

The East Coldstream Deposit is a structurally controlled gold deposit located approximately 13 km northeast of the Moss Deposit within the Moss Gold Project area. The East Coldstream Deposit’s mineralized zones are located on the south margin of a shear zone that separates a gabbroic intrusion to the north and a mafic-intermediate volcanic suite to the south. Mineralization is found within sheared volcanic units, proximal to sills of quartz and quartz-feldspar porphyries and distinctive, brick-red syenites. The mineralized zones show silica, carbonate, and hematite alteration. Mineralization consists of fine disseminations of pyrite and lesser chalcopyrite throughout the silica-hematite zones and within quartz-carbonate veinlets. Iron carbonate is present in areas proximal to strong silicification. A north-south-trending diabase dike has cut the two main mineralized zones.

Mineral Resource Methodology, Assumptions, and Cutoff Grades

Estimation Domains

APEX personnel comprehensively remodelled shear-hosted gold estimation domains at Moss and East Coldstream deposits using implicit modelling. The orientation of these domains is informed by a structural trend model derived from oriented core structural measurements. Additionally, APEX personnel developed an updated geological model to guide estimation domain modelling and facilitate density assignment by geological unit. The shear estimation domains are delineated by connecting intervals of mineralization that align with the structural trend and are predominantly within a single geological unit. Discontinuous and lower-grade gold mineralization associated with less intense shearing and more brittle deformation are captured within a grade shell with a nominal cutoff of 0.15 g/t Au.

The Granodiorite (IGD) unit at the Moss Lake Deposit is associated with zones of higher-grade mineralization. In the 2024 Moss Deposit MRE Update, modelled shear estimation domains are categorized as “Core Shears” or “Marginal Shears.” Core Shears, continuous along strike, represent higher-grade material within or adjacent to the IGD unit. Marginal Shears, in contrast, are shears positioned further from the IGD unit or within shear domains where lower-grade material is included to provide continuity along the structural trend. Core shears are characterized by more intense fracturing and extensive hydrothermal alteration than marginal shears. The Core and Marginal Shears classification merges short-range geological with longer-range structural continuity at the Moss Deposit.

In this 2024 model, more than 94% of the in pit block modelled gold mineralization tonnage above the cutoff grade is contained within the wireframed Core Shear and Marginal Shear domains. More than 96% of the block modelled gold mineralization in terms of metal content above the cutoff grade is also contained within the Core Shear and Marginal Shear domains.

Mineral Resource Methodology

Modelling was conducted in the Universal Transverse Mercator (UTM) coordinate space relative to the North American Datum (NAD) 1983 and UTM zone 15N (EPSG: 26915). The mineral resource block model utilized a block size of 3.0 m (X) x 3.0 m (Y) x 3.0 m (Z) to honour the mineralization wireframes. The percentage of the volume of each block below the bare earth surface, below the modelled waste overburden surface and within each mineralization domain was calculated using the 3D geological models and a 3D surface model. For the open pit resources, the block model was block-averaged up to a 9 m (X) x 9 m (Y) x 9 m (Z) SMU block size for pit optimization with the outer blocks on the boundaries of the domains diluted. Resources are presented as undiluted and in situ. The historical underground voids from Noranda’s 1980s exploration program have been removed from the MRE at the Moss Deposit.

The MRE is based on the combination of geological modelling, geostatistics and conventional block modelling using the Ordinary Kriging method of grade interpolation with locally varying anisotropy variogram models.

The Moss Project drillhole database consists of 538 drill holes that intersected the interpreted mineralization wireframes at the Moss Deposit and 156 drill holes that intersected the interpreted mineralization wireframes at the East Coldstream Deposit for a total of 738 Drill Holes used in the Mineral Resource Estimate. Gold assays were composited to 2-meter composite lengths, and the estimation utilized 31,149 composited samples. A total of 1.8% of the total drilled meters inside the interpreted mineralization wireframes were not sampled, assumed to be waste, and assigned a nominal waste value of half the detection limit of modern assay methods (0.0025 g/t Au).

Gold estimation was completed using ordinary kriging. The search ellipsoid size used to estimate the Au grades was defined by the modelled variograms. Block grade estimation employed locally varying anisotropy, which uses different rotation angles to define the principal directions of the variogram model and search ellipsoid on a per-block basis. Blocks within estimation domains are assigned rotation angles using a modelled 3D mineralization trend surface wireframe, which allows structural complexities to be reproduced in the estimated block model. The number of variogram structures, contributions of each structure, and their ranges are set per estimation domain and do not vary within the estimation domain.

A total of 2,812 bulk-density samples are available from the Moss Project drillhole database. APEX personnel performed exploratory data analysis of the bulk density samples available, and the density was assigned for each geologic unit modelled within the Moss Lake Deposit and East Coldstream Deposit areas. The density of the deposits ranged from 2.68 g/cm3 to 2.89 g/cm3. The modelled overburden was assigned a density of 1.8 g/cm3.

Mineral Resource Classification

The Moss Gold Project MRE has been classified as an Indicated and Inferred Mineral Resource. This resource classification reflects that much of the drill hole data used for the resource estimate is historical, and no QA/QC data or reports exist for most of these drill holes. Statistical assessment of historical data spatially near modern assay data support the use of the historical data in the mineral resource estimate including the indicated category of classification..

The resource is classified according to the CIM “Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines” dated November 29, 2019, and CIM “Definition Standards for Mineral Resources and Mineral Reserves” dated May 10, 2014.

Reasonable Prospects for Eventual Economic Extraction

The CIM guidelines for mineral resources require that reported mineral resources demonstrate reasonable prospects for eventual economic extraction (RPEEE). Table 4 outlines the cost parameters and other assumptions used to constrain the open-pit mineral resource statement and reporting cutoff. The resource block model underwent several pit optimization scenarios using Deswik’s Pseudoflow pit optimization. The resulting pit shell is used to constrain the reported open-pit MRE that reaches a maximum depth of approximately 510m and 340m in the Moss Deposit and East Coldstream Deposit, respectively.

Table 4: Open Pit RPEEE Cost and Parameter Assumptions

| Costs and Geometry | ||

| Parameter | Unit | 2024 MRE |

| Mining Waste | US$/ tonne waste | 2.25 |

| Mining Mineralized Material | US$/ tonne milled | 3.00 |

| Flotation Leach Processing | US$/ tonne milled | 9.50 |

| General and Administration | US$/ tonne milled | 2.10 |

| Slope | Degrees | 50 |

| Sale Price and Recoveries | ||

| Gold Recovery (Moss Lake) | Percent | 90 |

| Gold Recovery (East Coldstream) | Percent | 95 |

| Gold Price | US$/ozt | 1850 |

The reported underground MRE is constrained within mining shapes assuming open-stope mining methods, a grade cutoff of 2.0 g/t Au, and the assumptions detailed in Table 5. The mining shapes were manually constructed, constraining continuous material above the gold cutoff that met the minimum thickness and volume requirements.

Table 5: Underground RPEEE Cost and Parameter Assumptions

| Costs and Geometry | ||

| Parameter | Unit | 2024 MRE |

| Mining | US$/ tonne removed | 75 |

| Flotation Leach Processing | US$/ tonne milled | 9.50 |

| General and Administation | US$/ tonne milled | 2.10 |

| Assumed Open Stope Dimensions (W x H x L) | Meters | 1.5 x 10 x 20 |

| Sale Price and Recoveries | ||

| Gold Recovery (Moss Lake) | Percent | 90 |

| Gold Recovery (East Coldstream) | Percent | 95 |

| Gold Price | US$/ozt | 1850 |

Additional Exploration Potential

The modelled shears extend to much greater depth below the optimized open pit constraining the reported Moss MRE. The shears are also open along strike, beyond the modelled strike length of 5.7km. Historical drilling has intercepted gold mineralization over a total strike length of 8 km, which has been a focus of Goldshore’s 2023 soil geochemistry and structural mapping programs. This work suggests a series of en echelon “master shears” with a second prospective zone trending from just north of QES to the northeast beyond Span (Figures 2 to 4 and 8).

Furthermore, there remains potential for additional parallel shears with gold mineralization in historical drill holes up to 2.5km to the southeast of the Moss Deposit.

An additional 4 million tonnes of gold mineralization has been identified and modelled inside the conceptual open pit that is beyond the support distances required for Inferred or Indicated classification. This tonnage represents a target for future exploration drilling and resource development.

Similar to the Moss deposit, the modelled shears in East Coldstream extend to a greater depth below the optimized open pit constraining the reported MRE. The mineralization demonstrates a distinct shallow easterly plunge which has been successfully tested at depth by Goldshore drilling and represents potential for additional gold mineralization discoveries beneath the current defined MRE open pit (Figures 5 to 7).

Figure 8: Long section at the Moss Deposit showing gold mineralization in drillholes along strike and at depth looking northwest

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8051/196910_5cf9a22b6498bbf1_009full.jpg

Next Steps

Goldshore will also continue an extensive program of relogging and resampling of all historical drill holes whose collars have been located and accurately surveyed. Where possible, these drill holes are also being surveyed using modern downhole surveying equipment. Resampling of historical drill core will continue, although most core blocks are now illegible rendering resampling impossible.

Pete Flindell, VP Exploration for Goldshore, said: “APEX have completed a thorough and objective review of the geology of the Moss and East Coldstream Gold Deposits, and the underlying drill database. Their implicit modelling of core and marginal shears has led to a more accurate model of the gold distribution. This has resulted in a significant improvement in the Mineral Resource Estimate, which can now form the basis for infill and step out drill planning, and a definitive PEA. Their work also highlights immediate potential to grow the MRE in and outside of the RPEEE pits.“

Qualified Person Statements

Mr. Michael Dufresne, M.Sc., P.Geol., P.Geo. and Mr. Warren Black, M.Sc., P.Geo are both considered independent “qualified persons” under NI 43-101 and are jointly responsible for the 2024 Moss Gold Project MRE Update. Mr. Dufresne and Mr. Black have prepared and approved the scientific and technical information related to the MRE contained in this news release.

Peter Flindell, P.Geo., MAusIMM, MAIG, Vice President – Exploration of the Company, and a “qualified person” under NI 43-101 has also reviewed and approved the scientific and technical information contained in this news release.

Updated Technical Report

Details of the Moss Gold Project MRE will be provided in a technical report with an effective date of January 31, 2024, prepared in accordance with NI 43-101 standards, which will be filed under the Company’s SEDAR+ profile within 45 days of this news release. The Moss Gold Project MRE was prepared by independent mining consulting firm APEX Geoscience Ltd. in accordance with the Canadian Institute of Mining, Metallurgy and Petroleum (“CIM“) “Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines” dated November 29, 2019, and the CIM “Definition Standards for Mineral Resources and Mineral Reserves” dated May 10, 2014.

Results of the Company’s Annual General Meeting

The Company also announces that all matters proposed at the Annual General and Special Meeting (the “Meeting“) held on January 23, 2024 were approved. At the Meeting, shareholders of the Company voted in favour of setting the number of directors at six (6); as well as electing Galen McNamara, Brett Richards, Brandon Macdonald, Shawn Khunkhun, Joanna Pearson and Kyle Hickey as directors. The shareholders also approved the re-appointment of Davidson & Company LLP as the Company’s auditors, approved the adoption of a new omnibus incentive plan (the “Incentive Plan“) and provided disinterested approval ratifying a previous grant of restricted share units under the new Incentive Plan.

The new Incentive Plan replaces the existing stock option plan previously adopted by the Company, and allows for the grant of incentive stock options, restricted share units and deferred share units to a maximum of ten percent of the issued and outstanding share capital from time-to-time. For further information regarding the matters presented at the Meeting, or to review a copy of the new Incentive Plan, readers are encouraged to review the Company’s management proxy circular, a copy of which is available under the Company’s profile on SEDAR+.

About Goldshore

Goldshore is an emerging junior gold development company, and owns the Moss Gold Project located in Ontario. The Company is led and supported by an industry-leading management group, board of directors and advisory personnel. Goldshore is well-positioned and well financed to advance the Moss Gold Project through the next stages of exploration and development.

Neither the TSXV nor its Regulation Services Provider (as that term is defined in the policies of the TSXV) accepts responsibility for the adequacy or accuracy of this release.

For More Information — Please Contact:

Brett A. Richards

President, Chief Executive Officer and Director

Goldshore Resources Inc.

P. +1 604 288 4416 M. +1 905 449 1500

E. brichards@goldshoreresources.com

W. www.goldshoreresources.com

Facebook: GoldShoreRes | Twitter: GoldShoreRes | LinkedIn: goldshoreres

Cautionary Note Regarding Forward-Looking Statements

This news release contains statements that constitute “forward-looking statements.” Such forward looking statements involve known and unknown risks, uncertainties and other factors that may cause the Company’s actual results, performance or achievements, or developments to differ materially from the anticipated results, performance or achievements expressed or implied by such forward-looking statements. Forward looking statements are statements that are not historical facts and are generally, but not always, identified by the words “expects,” “plans,” “anticipates,” “believes,” “intends,” “estimates,” “projects,” “potential” and similar expressions, or that events or conditions “will,” “would,” “may,” “could” or “should” occur.

Forward-looking statements in this news release include, among others, statements relating to expectations regarding the exploration and development of the Project, the filing of a technical report supporting the MRE, commencement of a preliminary economic assessment and prefeasibility study, and other statements that are not historical facts. By their nature, forward-looking statements involve known and unknown risks, uncertainties and other factors which may cause our actual results, performance or achievements, or other future events, to be materially different from any future results, performance or achievements expressed or implied by such forward-looking statements. Such factors and risks include, among others: the Company may require additional financing from time to time in order to continue its operations which may not be available when needed or on acceptable terms and conditions acceptable; compliance with extensive government regulation; domestic and foreign laws and regulations could adversely affect the Company’s business and results of operations; the stock markets have experienced volatility that often has been unrelated to the performance of companies and these fluctuations may adversely affect the price of the Company’s securities, regardless of its operating performance; the impact of COVID-19; the ongoing military conflict in Ukraine; and other risk factors outlined in the Company’s public disclosure documents.

The forward-looking information contained in this news release represents the expectations of the Company as of the date of this news release and, accordingly, is subject to change after such date. Readers should not place undue importance on forward-looking information and should not rely upon this information as of any other date. The Company undertakes no obligation to update these forward-looking statements in the event that management’s beliefs, estimates or opinions, or other factors, should change.

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/196910