VANCOUVER, BC, Nov. 28, 2022 /CNW/ – Bravo Mining Corp. (TSXV: BRVO) (OTCQX: BRVMF) (“Bravo” or the “Company“) today announced that it has received assay results from the analysis of re-sampled historic drill core from an additional eight historical diamond drill holes (“DDH”) from its Luanga (palladium + platinum + rhodium + gold +nickel) project (“Luanga” or “Luanga PGM+Au+Ni“), located in the Carajás Mineral Province, state of Pará, Brazil.

“Assay results have been received from a total of 42 re-sampled historic drill holes to date, with the previously noted positive trend of higher PGM+Au grades continuing to be observed in most intercepts as compared to historical intercepts,” said Luis Azevedo, Chairman and CEO of Bravo. “It is also encouraging that nickel sulphide grades are very comparable to the historical total nickel results, suggesting that very little nickel is tied up in silicates in the fresh rock. All these observations, combined with the first-time assaying for rhodium in many intercepts, are supportive as we work to validate Luanga’s historical mineral resource estimate of 142Mt @ 1.24 g/t Pd+Pt+Au and 0.11% Ni” (see Page 5 of this news release for important information in respect of the Historical Estimate).

Highlights

- Results from the ongoing re-sampling of historic drill core continue to show a tendency to exceed the tenor of historic intercept grades, with mineralized thicknesses directly comparable to the thicknesses reported for historic intercepts.

- Highlights of Bravo’s most recent re-sampling results are tabulated below, with details including comparisons to historic intercepts:

| HOLE-ID | FROM (m) | TO(m) | THICKNESS (m) | HISTORIC SGS PGM + Au (g/t) | BRAVO ALSPGM + Au (g/t) | HISTORICNi % (Total) | BRAVO**Ni % (Sulphide) | TYPE |

| PPT-LUAN-FD0072 | 79.0 | 86.0 | 7.0 | 1.19 | 1.50 | 0.09 | 0.08 | FR |

| PPT-LUAN-FD0082 | 44.0 | 68.0 | 24.0 | 1.59 | 2.08* | 0.18 | 0.21 | FR |

| PPT-LUAN-FD0112 | 0.0 | 30.0 | 30.0 | 1.34 | 2.34 | 0.24 | NA | Ox |

| And | 139.0 | 156.0 | 17.0 | 1.02 | 2.15 | 0.01 | 0.01 | FR/LS |

| Notes: | All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole. |

| Given the orientation of the hole and the mineralization, the intercept is estimated to be 80% to 90% of true thickness. | |

| Type: Ox = Oxide. LS = Low Sulphur. FR = Fresh Rock. Recovery methods and results will differ based on the type of mineralization. | |

| NA: Not Applicable as intercept is oxide or a mix of oxide and fresh rock mineralization. | |

| * = Includes Rh >1.00g/t result. Overlimit analyses pending. | |

| ** = Bravo’s nickel grades are sulphide nickel, and do not include non-recoverable silicate nickel, unlike historic total nickel assays. |

- 119 drill holes (including 8 metallurgical drill holes) have been completed so far in 2022, for a total of 20,409 metres (or 80% of the Phase 1 Drill Program). Currently, samples from 46 drill holes are at the assay laboratory pending results, and results from 34 drill holes have been released to date.

- 22,318 samples have been submitted for assay in 2022, including 3,353 samples from re-sampling of historic drill core.

- 6 drill rigs operating onsite.

Luanga Re-Sampling Program and Phase 1 Drilling Progress

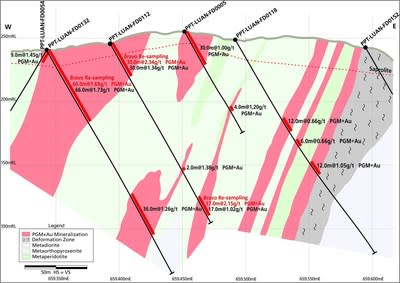

A comparison of the historic intercepts with the Bravo assay results from re-sampled core is tabulated below, with a plan showing the re-sampled hole locations. A drill section is provided below, showing results for PPT-LUAN-112. Bravo’s assay results from re-sampled core continue to closely correlate to the historic intercepts in thicknesses, while the previously observed trend of intercepts frequently exceeding the tenor of historic grades continues. This is most likely related to improved assay methods for PGMs versus those available over 20 years ago, and only sporadic rhodium assaying historically.

The Phase 1 diamond drill program continues as planned at Luanga. Six drill rigs are on site, with drilling progressing in various locations along the entire 8.1km strike length of the known Luanga mineralized envelope. To date, 114 drill holes have been completed, for a total of 19,384 metres (or 76%) of the planned 25,500 metre Phase 1 drill program.

Comparison of Re-Sampled Intercepts – Historic Intercept (SGS Laboratory) versus Bravo Intercept (ALS Laboratory)

| HOLE-ID | From (m) | To(m) | Thickness (m) | HISTORIC SGS PGM + Au (g/t) | BRAVO ALSPGM + Au (g/t) | HISTORICNi % (Total) | BRAVO**Ni % (Sulphide) | TYPE |

| PPT-LUAN-FD0072 | 44.0 | 60.0 | 16.0 | 0.72 | 0.71 | 0.16 | 0.18 | FR |

| And | 79.0 | 86.0 | 7.0 | 1.19 | 1.50 | 0.09 | 0.08 | FR |

| PPT-LUAN-FD0073 | 26.0 | 44.0 | 18.0 | 0.81 | 0.84 | 0.15 | 0.16 | FR |

| PPT-LUAN-FD0082 | 0.0 | 19.0 | 19.0 | 0.81 | 0.83 | 0.10 | NA | Ox |

| And | 44.0 | 68.0 | 24.0 | 1.59 | 2.08* | 0.18 | 0.21 | FR |

| And | 81.0 | 84.0 | 3.0 | 0.90 | 1.00 | 0.09 | 0.08 | FR |

| PPT-LUAN-FD0083 | 57.0 | 63.0 | 6.0 | 0.28 | 0.23 | 0.15 | 0.13 | FR |

| And | 68.0 | 74.0 | 6.0 | 0.17 | 0.14 | 0.11 | 0.09 | FR |

| PPT-LUAN-FD0096 | 292.0 | 307.0 | 15.0 | 0.50 | 0.48 | 0.10 | 0.10 | FR |

| PPT-LUAN-FD0112 | 0.0 | 30.0 | 30.0 | 1.34 | 2.34 | 0.24 | NA | Ox |

| And | 139.0 | 156.0 | 17.0 | 1.02 | 2.15 | 0.01 | 0.01 | FR/LS |

| Notes: | All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole. |

| Given the orientation of the hole and the mineralization, the intercept is estimated to be 80% to 90% of true thickness. | |

| Type: Ox = Oxide. LS = Low Sulphur. FR = Fresh Rock. Recovery methods and results will differ based on the type of mineralization. | |

| NA: Not Applicable as intercept is oxide or a mix of oxide and fresh rock mineralization. | |

| * = Includes Rh >1.00g/t result. Overlimit analyses pending. | |

| ** = Bravo’s nickel grades are sulphide nickel, and do not include non-recoverable silicate nickel, unlike historic total nickel assays. |

Complete Table of New Intercepts for Re-sampled holes

| HOLE-ID | From (m) | To(m) | Thickness (m) | Pd(g/t) | Pt(g/t) | Rh(g/t) | Au (g/t) | PGM + Au (g/t) | Ni % (Sulphide) | TYPE |

| PPT-LUAN-FD0072 | 44.0 | 60.0 | 16.0 | 0.38 | 0.21 | 0.04 | 0.09 | 0.71 | 0.18 | FR |

| And | 79.0 | 86.0 | 7.0 | 0.87 | 0.50 | 0.10 | 0.02 | 1.50 | 0.08 | FR |

| PPT-LUAN-FD0073 | 26.0 | 44.0 | 18.0 | 0.44 | 0.25 | 0.01 | 0.15 | 0.84 | 0.16 | FR |

| PPT-LUAN-FD0082 | 0.0 | 19.0 | 19.0 | 0.61 | 0.18 | 0.01 | 0.03 | 0.83 | NA | Ox |

| And | 44.0 | 68.0 | 24.0 | 1.22 | 0.62 | 0.20* | 0.03 | 2.08* | 0.21 | FR |

| And | 81.0 | 84.0 | 3.0 | 0.68 | 0.26 | 0.05 | 0.01 | 1.00 | 0.08 | FR |

| PPT-LUAN-FD0083 | 57.0 | 63.0 | 6.0 | 0.12 | 0.09 | 0.01 | <0.01 | 0.23 | 0.13 | FR |

| And | 68.0 | 74.0 | 6.0 | 0.09 | 0.04 | 0.01 | 0.01 | 0.14 | 0.09 | FR |

| PPT-LUAN-FD0096 | 292.0 | 307.0 | 15.0 | 0.25 | 0.17 | 0.03 | 0.04 | 0.48 | 0.10 | FR |

| PPT-LUAN-FD0112 | 0.0 | 30.0 | 30.0 | 1.38 | 0.82 | 0.11 | 0.04 | 2.34 | NA | Ox |

| And | 139.0 | 156.0 | 17.0 | 0.77 | 1.17 | 0.19 | 0.02 | 2.15 | 0.01 | FR/LS |

| Notes: | All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole. |

| Given the orientation of the hole and the mineralization, the intercept is estimated to be 80% to 90% of true thickness. | |

| Type: Ox = Oxide. LS = Low Sulphur. FR = Fresh Rock. Recovery methods and results will differ based on the type of mineralization. | |

| NA: Not Applicable as intercept is oxide or a mix of oxide and fresh rock mineralization. | |

| * = Includes Rh >1.00g/t result. Overlimit analyses pending. |

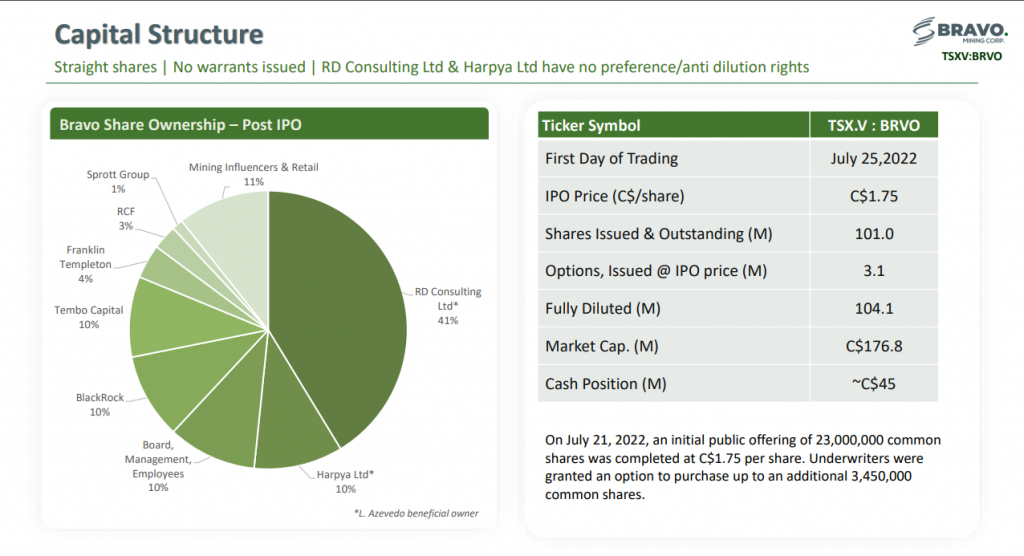

About Bravo Mining Corp.

Bravo is a Canada and Brazil-based mineral exploration and development company focused on advancing its Luanga PGM + Au + Ni Project in the world-class Carajás Mineral Province of Brazil.

The Luanga Project benefits from being in a location close to operating mines, with excellent access and proximity to existing infrastructure, including road, rail and clean and renewable hydro grid power. The project area was previously de-forested for agricultural grazing land. Bravo’s current Environmental, Social and Governance activities includes replanting trees in the project area, hiring and contracting locally, engagement with local communities, and ensuring protection of the environment during its exploration activities.

Technical Disclosure

Technical information in this news release has been reviewed and approved by Simon Mottram, F.AusIMM (Fellow Australia Institute of Mining and Metallurgy), President of Bravo Mining Corp. who serves as the Company’s “qualified person”, as defined in National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101“). Mr. Mottram has verified the technical data and opinions contained in this news release.

Historical Resource Estimate

This press release includes a historical resource estimate for the Luanga Project (the “Historical Estimate“) prepared internally by prior owners, VALE SA, in 2017 and contained in a report by Mansur E.T., Ferreira Filho C.F., Oliveira D.P.L. entitled “The Luanga deposit, Carajás Mineral Province, Brazil: Different styles of PGE mineralization hosted in a medium-size layered intrusion.” and published in Ore Geology Reviews (Volume 118, March 2020, 103340). A qualified person has not done sufficient work to classify the Historical Estimate as current mineral resources or mineral reserves under National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”) and Bravo is not treating the Historical Estimate as current mineral resources or mineral reserves. Bravo cautions that the Historical Estimate was not prepared in accordance with NI 43-101. There can be no certainty, following further evaluation and/or exploration work, that the Historical Estimate can be upgraded or verified as mineral resources or mineral reserves in accordance with NI 43-101. Further, the assays values used to calculate the nickel content in the Historical Estimate are total nickel, and thus contain both sulphide nickel (potentially recoverable) and silicate nickel (unrecoverable by conventional methods). Bravo is not aware whether the nickel content in the Historical Estimate has been modified to account for this or not. In addition, no breakdown of the assay results for the individual metals contributing to this Historical Estimate has been published and the Historical Estimate was not classified in accordance with the mineral resource categories set out in NI 43-101. Nevertheless, Bravo considers the Historical Estimate to be relevant to the reader’s understanding of the status of the Project and its future potential.

Forward Looking Statements

This news release contains forward-looking information which is not comprised of historical facts. Forward-looking information is characterized by words such “outperform”, “highlights”, “positive trend”, “encouraging”, “inspiring”, “exceeding”, “correlate”, “exceeding”, “improved”, “validate” and other similar words, phrases or statements that certain events or conditions “could”, “should”, “potentially” or “will” occur. In particular, this news release contains forward-looking information pertaining to the Company’s ongoing re-sampling and drill programs and the results thereof; the potential for a continued trend of improved in grade relative to historic assays and the possible impact on future mineral resource estimates; the potential for the definition of new styles of mineralization and extensions to depth and the Company’s plans in respect thereof. Forward-looking information involves risks, uncertainties and other factors that could cause actual events, results, and opportunities to differ materially from those expressed or implied by such forward-looking information. Factors that could cause actual results to differ materially from such forward-looking information include, but are not limited to, changes in the state of equity and debt markets, re-sampling results may vary negatively from historical results, fluctuations in commodity prices, delays in obtaining required regulatory or governmental approvals, environmental risks, limitations on insurance coverage; and other risks and uncertainties involved in the mineral exploration and development industry. Forward-looking information in this news release is based on the opinions and assumptions of management considered reasonable as of the date hereof, including, but not limited to, the assumption that the assay results confirm the interpreted mineralization contains significant values of nickel, copper and also contain PGMs and Au; final drill and assay results will be in line with management’s expectations; that sample grades from re-assayed core may continue to outperform historic grades; that activities will not be adversely disrupted or impeded by regulatory, political, community, economic, environmental and/or healthy and safety risks; that the Luanga Project will not be materially affected by potential supply chain disruptions; and general business and economic conditions will not change in a materially adverse manner. Although the Company believes that the assumptions and factors used in preparing the forward-looking information in this news release are reasonable, undue reliance should not be placed on such information. The Company disclaims any intention or obligation to update or revise any forward-looking information, other than as required by applicable securities laws.

Schedule 1: Drill Hole Collar Details

| HOLE-ID | Company | East (m) | North (m) | RL (m) | Datum | Depth (m) | Azimuth | Dip | Sector |

| PPT-LUAN-FD0072 | Vale SA | 659387.11 | 9341285.56 | 226.76 | SIRGAS2000 UTM22S | 231.00 | 330.0 | -60.0 | Central |

| PPT-LUAN-FD0073 | Vale SA | 659211.28 | 9341185.85 | 226.30 | SIRGAS2000 UTM22S | 229.10 | 330.0 | -60.0 | Central |

| PPT-LUAN-FD0082 | Vale SA | 659734.39 | 9341481.67 | 206.98 | SIRGAS2000 UTM22S | 213.20 | 330.0 | -60.0 | Central |

| PPT-LUAN-FD0083 | Vale SA | 659904.92 | 9341589.34 | 233.28 | SIRGAS2000 UTM22S | 216.65 | 330.0 | -60.0 | Central |

| PPT-LUAN-FD0096 | Vale SA | 659609.30 | 9341300.37 | 201.82 | SIRGAS2000 UTM22S | 320.40 | 360.0 | -90.0 | Central |

| PPT-LUAN-FD0112 | Vale SA | 659393.12 | 9343373.87 | 244.94 | SIRGAS2000 UTM22S | 160.90 | 90.0 | -60.0 | North |

Schedule 2: Assay Methodologies and QAQC

Samples followed chain of custody between collection, processing and delivery to the ALS laboratory in Parauapebas, state of Pará, Brazil. The drill core was delivered to the core shack at Bravo’s Luanga site facilities and processed by geologists who inserted certified reference materials, blanks and duplicates into the sampling sequence. Drill core was quarter cut and placed in secured polyurethane bags, then in security-sealed sacks before being delivered directly from the Luanga site facilities to the Parauapebas ALS laboratory by Bravo staff. Additional information about the methodology can be found on the respective ALS or SGS global websites (ALS, SGS) in their analytical guides. Information regarding preparation and analysis of historic drill core is also presented in the table below, where the information is known.

Quality Assurance and Quality Control (“QAQC“) is maintained internally at the lab through rigorous use of internal certified reference materials, blanks, and duplicates. An additional QAQC program is administered by Bravo using certified reference materials, duplicate samples and blank samples that are blindly inserted into the sample batch. If a QAQC sample returns an unacceptable value an investigation into the results is triggered and when deemed necessary, the samples that were tested in the batch with the failed QAQC sample are re-tested.

| Bravo ALS | ||||||

| Preparation | Method | Method | Method | Method | ||

| For All Elements | Pt, Pd, Au | Rh | Ni-Sulphide | Trace Elements | ||

| PREP-31B | PGM-ICP27 | Rh-MS25 | Ni-ICP05 | ME-ICP61 | ||

| Historic Drill Assaying SGS Geosol | ||||||

| Preparation | Method | Method | Method | Method | ||

| For All Elements | Pt, Pd, Au | Rh | TOTAL Ni | Trace Elements | ||

| Crushed to <200# mesh | FA30A | FA30B | ICP-117 | ICP-117 | ||

SOURCE Bravo Mining Corp.

View original content to download multimedia: http://www.newswire.ca/en/releases/archive/November2022/28/c1151.html