North Vancouver, British Columbia–(Newsfile Corp. – June 28, 2023) – Lion One Metals Limited (TSXV: LIO) (OTCQX: LOMLF) (ASX: LLO) (“Lion One” or the “Company”) is pleased to provide an update on construction progress at its 100% owned Tuvatu Alkaline Gold Project in Fiji.

Highlights:

- Mine construction is approximately 75% complete.

- Earthworks and concrete works are substantially complete, structural steel is 70% complete.

- The project is fully funded and on track for delivery of first gold in Q4 CY 2023.

Figure 1. Tuvatu Gold Mine Under Construction. See below for additional images.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/2178/171562_bb6a2eed54d89a8e_001full.jpg

Mine construction is approximately 75% complete and remains on track for delivery of first gold in Q4 2023. Earthworks and concrete works are substantially complete, with over 3,500 m3 of concrete poured to date. Structural steel is 70% complete and is progressing rapidly. All the components required to commission the processing plant are on site and a team of 350 contractors and employees are working together to bring the project towards completion. Once complete, Lion One plans to operate the processing plant at an initial production capacity of 300 tonnes per day for the first 18 months of operations before increasing the capacity to 500 tonnes per day in mid-2025. Lion One is fully funded to complete mine construction and bring the Tuvatu Alkaline Gold Project into production by the end of the year.

Videos of construction progress can be viewed on the company’s website (www.liononemetals.com). A summary of construction items that are in progress or complete is shown in Table 1 below.

Site Infrastructure

A large portion of the site infrastructure is complete, including the site office, the mine changeroom, the mine workshop, the fresh water supply system, the sewage treatment plant and the waste rock crusher and screener, all of which are commissioned and in use. The construction of the power plant, which consists of six 800 KW generators and one 1,500 KW generator for a total 6.3 MW, is in progress.

Crushing and Conveying

The Lion One processing plant will treat material using a two-stage crushing process, with a primary jaw crusher and a secondary cone crusher. A system of three conveyor belts will transport material between the two crushers and on to the processing plant. The jaw crusher, cone crusher, conveyor belt 1 and conveyor belt 2 are all in place while conveyor belt 3 has been fabricated and needs to be lifted into place. Piping and electrical work remains to be completed. The ROM pad has also been constructed and is in use, with minor upgrades remaining to be completed.

Grinding, Concentrating, Leaching and Recovery

Material from the crushing process will be fed to a two-stage grinding circuit, followed by an integrated two-stage gravity concentration circuit. Some concentrates will then be treated by an intensive cyanide leaching reactor and the remainder of the concentrates will be leached using conventional cyanide Carbon in Leach (CIL) technology. Gold will be recovered from the gold laden carbon using conventional absorption desorption recovery (ADR) technology and smelted on site to produce gold doré bars. Construction is advancing rapidly on the grinding, concentrating, and leaching circuits, as well as on the necessary supporting infrastructure such as warehouses and workshops. Ball Mills 1 and 2 are in place, the leaching tanks are in place, and Reagent Warehouse 1 is nearing completion. All other components of the processing plant are in progress at varying levels of completion. Electrical and piping work remains to be completed.

Tailings Storage Facility (TSF)

Tailings from the processing plant will be treated using the SO2/air process to remove any residual cyanide and will be filtered to produce filtered tailings which will then be transported to the TSF for storage. Stage 1 of the TSF will consist of a dam with a finish level at 115 m elevation, and a pond with enough capacity for 18 months of operation. The tailings dam has currently been built to an elevation of 107 m. TSF construction has been ongoing since June 2022 and the TSF is anticipated to be in operation in Q4 of 2023. Other components of the TSF, such as diversion channels, dam spillway, and liner installation are advancing simultaneously.

Underground Developments

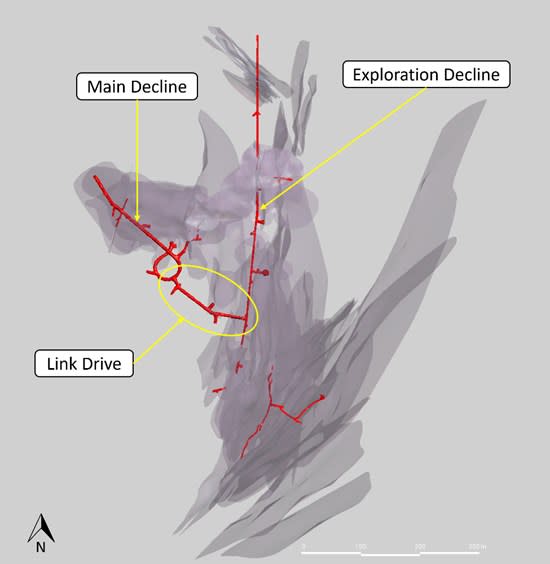

Underground mining of the URA1 , URW1a and URW1b lodes is ongoing. The main decline has reached a vertical depth of 99.4 m below surface and a total length of 344 m from the mine portal. The link drive connecting the main decline to the historical exploration decline has been completed and measures 140 m from the junction with the main decline to the junction with the historical exploration decline. The link decline was driven from the main decline to the exploration decline and broke through the exploration decline on June 21st, 2023.

The completion of the link drive is a major milestone in the development of the mine as it enables the Stage 1 primary ventilation system to be installed. The Stage 1 primary ventilation system consists of four 55KW exhaust fans that are being installed at the entrance to the historical exploration decline, and which will provide ventilation throughout the mine. The Stage 1 primary ventilation system will provide sufficient ventilation to mine all the way down to the 500 zone, which is part of the high-grade feeder zone underlying Tuvatu and which comprises a major component of the mine plan. The completion of the link drive also enables mineralized lodes to be mined both from the historical exploration decline as well as from the main decline, thereby increasing the number of faces available to mine and adding considerable flexibility to the mining operations.

In addition to the link drive and ventilation system, a high voltage power plant and an underground compressor are also being installed to support underground mining operations.

Table 1. Status of Major Mine Components Under Construction.

| Processing Plant | |

| Item | Construction/Installation Progress |

| ROM Pad | Nearing Completion |

| Jaw Crusher | Complete |

| Cone Crusher | Complete |

| Conveyor Belt 1 | Nearing Completion |

| Conveyor Belt 2 | Nearing Completion |

| Conveyor Belt 3 | In Progress |

| Ball Mill 1 | Complete |

| Ball Mill 2 | Complete |

| Gravity Circuit | In Progress |

| Intensive Leaching Circuit | In Progress |

| Leaching Tanks | Nearing Completion |

| Filter Press System | In Progress |

| Reagent Warehouse 1 | Nearing Completion |

| Reagent Warehouse 2 | In Progress |

| Electrowinning and Carbon Regeneration Workshop | In Progress |

| Gold Room | In Progress |

| Main Power Plant | In Progress |

| Supporting Infrastructure | |

| Item | Construction/Installation Progress |

| Mine Changeroom | Complete |

| Mine Workshop | Complete |

| Site Office | Complete |

| Surface Magazine Storage | Complete |

| Mill Maintenance Workshop | Planning |

| Site CCTV and Fibre Optic Cable Installation | Nearing Completion |

| Fresh Water Supply System | Complete |

| Sewage Treatment Plant (STP) | Complete |

| Diesel Generator Power Plant Installation | In Progress |

| Waste Rock Crusher and Screener | In Production |

| Water Retention Pond | Complete |

| Coreshed Expansion | Complete |

| Tailings Storage Facility (TSF) | |

| Item | Construction/Installation Progress |

| Tailings Dam (Stage 1) | In Progress |

| North Diversion Channel | Complete |

| South Diversion Channel | In Progress |

| TSF Basin Excavation | In Progress |

| TSF Dam Spillway | In Progress |

| HDPE Liner Installation | In Progress |

| Underground Developments/Upgrades | |

| Item | Construction/Installation Progress |

| Link Drive Connecting Main and Exploration Declines | Complete |

| HV Power Plant | In Progress |

| UG Compressor Installation | In Progress |

| Stage 1 Primary Ventilation | In Progress |

Images

Figure 2. Oblique aerial view of mine site under construction, June 16, 2023.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/2178/171562_bb6a2eed54d89a8e_002full.jpg

Figure 3. Aerial view of mine portal, ROM pad, and crushing plant, June 16, 2023.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/2178/171562_bb6a2eed54d89a8e_003full.jpg

Figure 4. Aerial view of processing plant.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/2178/171562_bb6a2eed54d89a8e_004full.jpg

Figure 5. Vertical aerial view of mine site under construction, June 16, 2023.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/2178/171562_bb6a2eed54d89a8e_005full.jpg

Figure 6. Aerial view of TSF under construction, June 16, 2023.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/2178/171562_bb6a2eed54d89a8e_006full.jpg

Figure 7. Location of link drive in relation to the main decline and the historical exploration decline. Mineralized lodes are shown in transparent grey. Connecting the main decline to the exploration decline enables the Stage 1 primary ventilation system to be installed and enables mining of the lodes accessed through the exploration decline.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/2178/171562_bb6a2eed54d89a8e_007full.jpg

About Tuvatu

The Tuvatu Alkaline Gold Project is located on the island of Viti Levu in Fiji. The January 2018 mineral resource for Tuvatu as disclosed in the technical report “Technical Report and Preliminary Economic Assessment for the Tuvatu Gold Project, Republic of Fiji”, dated September 25, 2020, and prepared by Mining Associates Pty Ltd of Brisbane Qld, comprises 1,007,000 tonnes indicated at 8.50 g/t Au (274,600 oz. Au) and 1,325,000 tonnes inferred at 9.0 g/t Au (384,000 oz. Au) at a cut-off grade of 3.0 g/t Au. The technical report is available on the Lion One website at www.liononemetals.com and on the SEDAR website at www.sedar.com.

Qualified Person

In accordance with National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“NI 43- 101”), Patrick Hickey, Chief Operating Officer, is the Qualified Person for the Company and has reviewed and is responsible for the technical and scientific content of this news release.

About Lion One Metals Limited

Lion One’s flagship asset is 100% owned, fully permitted high grade Tuvatu Alkaline Gold Project, located on the island of Viti Levu in Fiji. Lion One envisions a low-cost high-grade underground gold mining operation at Tuvatu coupled with exciting exploration upside inside its tenements covering the entire Navilawa Caldera, an underexplored yet highly prospective 7km diameter alkaline gold system. Lion One’s CEO Walter Berukoff leads an experienced team of explorers and mine builders and has owned or operated over 20 mines in 7 countries. As the founder and former CEO of Miramar Mines, Northern Orion, and La Mancha Resources, Walter is credited with building over $3 billion of value for shareholders.

On behalf of the Board of Directors of

Lion One Metals Limited

“Walter Berukoff“, Chairman and CEO

Contact Investor Relations

Toll Free (North America) Tel: 1-855-805-1250

Email: info@liononemetals.com

Website: www.liononemetals.com

Neither the TSX Venture Exchange nor its Regulation Service Provider accepts responsibility for the adequacy or accuracy of this release

This press release may contain statements that may be deemed to be “forward-looking statements” within the meaning of applicable Canadian securities legislation. All statements, other than statements of historical fact, included herein are forward-looking information. Generally, forward-looking information may be identified by the use of forward-looking terminology such as “plans”, “expects” or “does not expect”, “proposed”, “is expected”, “budget”, “scheduled”, “estimates”, “forecasts”, “intends”, “anticipates” or “does not anticipate”, or “believes”, or variations of such words and phrases, or by the use of words or phrases which state that certain actions, events or results may, could, would, or might occur or be achieved. This forward-looking information reflects Lion One Metals Limited’s current beliefs and is based on information currently available to Lion One Metals Limited and on assumptions Lion One Metals Limited believes are reasonable. These assumptions include, but are not limited to, the actual results of exploration projects being equivalent to or better than estimated results in technical reports, assessment reports, and other geological reports or prior exploration results. Forward-looking information is subject to known and unknown risks, uncertainties and other factors that may cause the actual results, level of activity, performance or achievements of Lion One Metals Limited or its subsidiaries to be materially different from those expressed or implied by such forward-looking information. Such risks and other factors may include, but are not limited to: the stage development of Lion One Metals Limited, general business, economic, competitive, political and social uncertainties; the actual results of current research and development or operational activities; competition; uncertainty as to patent applications and intellectual property rights; product liability and lack of insurance; delay or failure to receive board or regulatory approvals; changes in legislation, including environmental legislation, affecting mining, timing and availability of external financing on acceptable terms; not realizing on the potential benefits of technology; conclusions of economic evaluations; and lack of qualified, skilled labour or loss of key individuals. Although Lion One Metals Limited has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking information, there may be other factors that cause results not to be as anticipated, estimated or intended. Accordingly, readers should not place undue reliance on forward-looking information. Lion One Metals Limited does not undertake to update any forward-looking information, except in accordance with applicable securities laws.

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/171562